At the point when you begin discussing air suspensions, the essential thought isn’t too difficult to get a handle on. As the name recommends, rather than metal curls or leaf springs, an air suspension framework utilizes air springs. Also, since the air should be contained in some way or another, the air springs look more like elastic inflatables than springs.

In any case, past that, what’s the reason? How can it work? What points of interest are there to an air suspension? What’s more, for what reason do you see them utilized in everything from pickup trucks to extravagance vehicles and exceptionally changed low riders?

Definition of the air suspension system

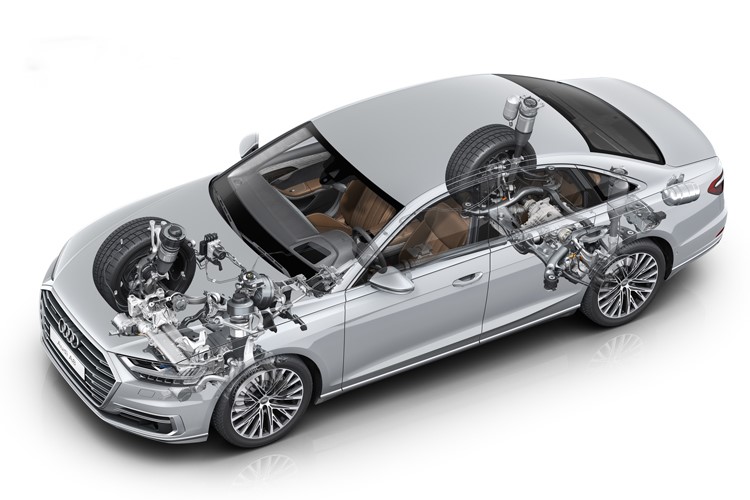

An air suspension system defines a vehicle suspension that is organized by an electric siphon or blower that siphons air into adaptable howls that are normally made out of a material fortified kind of elastic. Air suspension can also be portrayed as a substitution to the leaf suspension or curl spring framework with airbags made out of polyurethane and elastic. A blower expands the airbags depending upon the particular pressing factor to carry on like springs. Air suspension then varies from hydropneumatic suspension as they use pressurized air instead of pressurized fluid.

Principle of air suspension system in the vehicle

The auto programmed control of the airbag pressure is defined by a strong state electronic control framework explicitly planned and bundled for vehicle use. This framework persistently screens the “ride stature” of the trailer suspension and expands pneumatic force if the ride height is excessively low, by turning on an on-board air blower. The air blower stops naturally when the appropriate ride tallness is reached. If the ride stature is excessively high, a programmed vent valve vents abundance gaseous tension and quits venting when the legitimate ride tallness is reached. All necessary electrical force is given by a 12-volt battery contained in the trailer gear compartment.

Working of air suspension system in the vehicle

Instead of the spring is a bellow loaded up with air. Under burden, the bellow is packed, causing a diminishing in volume and an expansion in pressing factor.

If more air is siphoned in, the roar is re-established to its typical volume or, all the more essentially, it’s ordinary height. As an air spring, the expanded pressing factor implies expanded hardness, which is essential for the additional weight. Then the vehicle’s ride stature stays steady.

Air suspension system presently include in various upmarket cantinas, sports used vehicles, and station carts. Some of them have air suspension just at the back.

The upside of this is in any event when the boot is completely loaded, the vehicle stays level. Supporting the air-filled howls or air suspension are various parts not present in the customary steel-sprung suspension framework. One of them is an electric or belt-driven blower to supply air into the howls when called for.

Pros of the air suspension system

Air suspension has some huge favorable circumstances over conventional coil or leaf spring suspension on trucks and trailers. It is an arrangement of elastic and polyurethane packs, expanded by a blower, which substitutes for coils or leaf spring suspension.

Driver’s comfort–

Drivers that spend quite a while in the taxi are presented to ‘NVH’ (noise, vibration, and harshness). These can cause weakness, a terrible back, and hearing misfortune (if the truck is exceptionally uproarious) and that’s just the beginning. Exhaustion is a major executioner, so anything that lessens the odds of a driver nodding off at the worst possible time is something to be thankful for. Making the truck more agreeable likewise implies less time off work with a throbbing painfulness.

Less wear and tear–

Air suspension implies less vibration through the vehicle and that implies less mileage on parts on the truck or trailer. Tire wear is improved because of smoother suspension qualities, and a few frameworks can lift axles that aren’t required, drawing out tire life.

Environmental economy–

Less vibration is communicated through the surface over the street implying that the street surface (which additionally incorporates spans and different structures connected to the street) doesn’t corrupt as fast. This implies that streets don’t need to be fixed as now and again; fixes lead to gridlock in addition to the related hardware and materials to impact the maintenance, all of which cause contamination.

Increased efficiency–

The ride height can be improved depending on the speed, kind of surface, and whether the truck is loaded or void. Generally, an unladen truck will be taller than a loaded truck because the suspension isn’t packed, yet with air suspension, the ride stature can be brought down. Going with lower ride height implies better optimal design and cornering execution.

Cons of the air suspension system

- Air suspension is more costly to fit and requires more support than customary leaf spring suspension.

- Drivers need to realize how to take advantage of it by utilizing the settings accurately.

- For certain applications, air suspension has practically no effect.

- Air suspension gauges more than leaf suspension.

Final verdict

Air suspension systems are intricate and daunting, yet they can yield amazing looks and execution whenever introduced and tuned accurately.