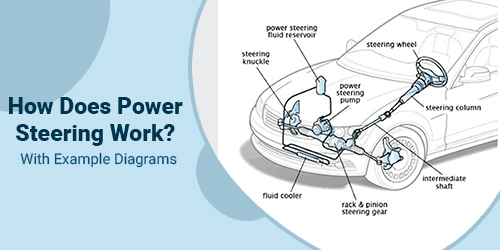

Vehicle dynamics is an integral part of a motor vehicle, and it is as important as the vehicle’s drivetrain, because if we need the drivetrain to run the vehicle, we also need the vehicle dynamics system to maintain the vehicle’s power. In its most basic form, power steering is a system that reduces the force required by the driver to turn the steering wheel. Without assistance, most vehicles will have very heavy steering, especially when operating at low speeds such as parking, turning at a 90-degree angle in a town or passing a crowded gas station. History The first power steering system installed on a production car made its debut on the Chrysler Empire in 1951, and competition soon followed. Power steering is not only obvious—it allows the driver to drive heavy vehicles with less effort and greater comfort—but it also allows engineers to improve the steering response, that is, the speed at which the car changes direction.

Vehicle dynamics is an integral part of a motor vehicle, and it is as important as the vehicle’s drivetrain, because if we need the drivetrain to run the vehicle, we also need the vehicle dynamics system to maintain the vehicle’s power. The vehicle runs stably. As we know, the suspension system is part of vehicle dynamics. It provides contact with the surface and the turning stability of the vehicle, but let us thinks about it, turning in the direction of the vehicle while moving will cause a lot of force. This raises many questions, such as how to do it?

What are the requirements to turn the vehicle in the desired direction? To find these answers, let’s do more research. The automobile steering system is an integral part of vehicle dynamics, in which a number of mechanical components with certain important angles come together to steer the front wheels of the vehicle in accordance with input provided by the passenger through the steering wheel. The power steering system is an advanced steering system in which the force applied by the driver through the steering wheel is doubled by using an intermediate electrical or hydraulic device to reduce the force required to steer the front wheels of the vehicle to achieve a smooth and fast speed. reverse the vehicle. Today, 80% of cars on the road are equipped with power steering system, which has become the basic demand of today’s cars.

Why do we need power steering?

As we have discussed above, power steering reduces the steering force required for four-wheelers, so we need power steering to respond quickly for the following reasons: with the increase in the number of vehicles on the road all the days and today, almost 60 in the world there is a four-wheeler in the house of a man of a mile. With the increase in the number of vehicles, the risk of accidents on the road also increases. Therefore, to avoid this hazard and turn quickly as needed, the four-wheeler must respond quickly to the steering system.

Steering Power: If we drive an old car like Maruti Suzuki 800 and find that when the speed is less than 40 km / h, the steering wheel feels very difficult to turn, this is on long -Distance driving time will cause driver fatigue. Therefore, the vehicle must be equipped with a power steering system to reduce the steering force required to steer the front wheels.

Impact Steering: As we know, the suspension system reduces shocks on the road, but because the steering system is directly connected to the wheel hub, part of the impact force will also be transferred to the steering system, and the steering system tries. for driving, although it may provide the best scrub The radius is used to mechanically control bumpy steering, but the vehicle will go against of the driver’s will, so the vehicle may lose stability but the power steering controls it more effectively.

Rollover Capability-After turning, it is found that the steering will automatically return to its original position, thereby automatically straightening the driving vehicle. Vehicles equipped with a power steering system can provide better feedback capabilities for the steering system.

Types of Power Steering System

According to the method used to multiply the steering force, there are 3 types of power steering systems, namely

1. The hydraulic power steering system

It has a hydraulic pump driven by a motor and a hydraulic cylinder to increase the input force of the steering wheel, thus reducing the force required to steer the front wheels of the vehicle. The hydraulic cylinder uses highly compressed hydraulic oil to apply pressure to the steering gear.

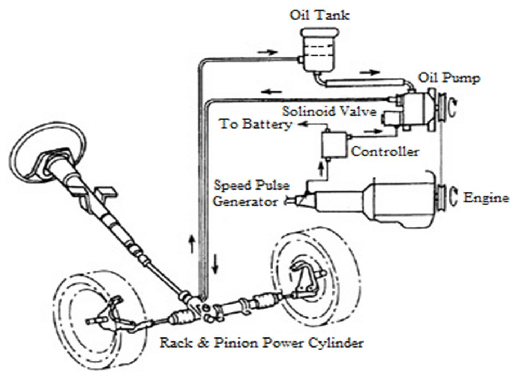

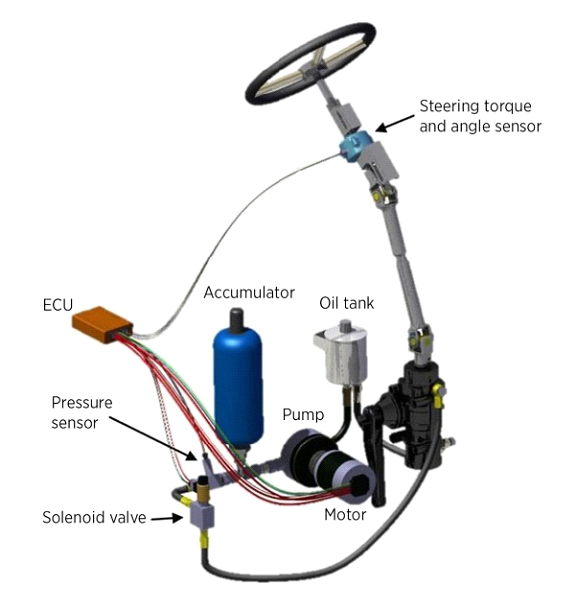

2. Electro-Hydraulic Power Steering System – An Improved Version of Hydraulic System The motor-driven rotary hydraulic pump in the hydraulic power steering system is changed to a hydraulic pump driven by an electric motor. Because it uses hydraulic and electrical components, it is also called a hybrid power steering system.

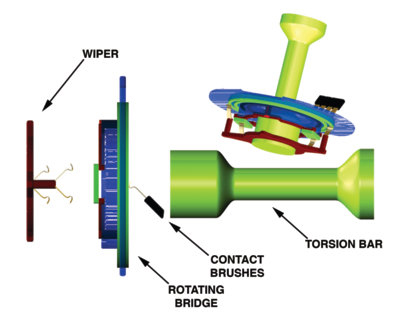

3. Electronic Power Steering System – This is the latest type of power steering system, in which the hydraulic power steering system is completely replaced by electric motors and electric sensors, rather than using hydraulic pressure. The electric motor driven by the vehicle `The motor applies force and the torque provided by the motor is controlled by a sensor that detects the position of the steering column. The steering response of this system is fast and very efficient, which is why it is used in almost all new cars today.

Power steering system operation

The power steering system operation differs depending on the force multiplier device used. Therefore, to understand the operation of power steering, these three methods need to be discussed separately.

1. Hydraulic power steering system

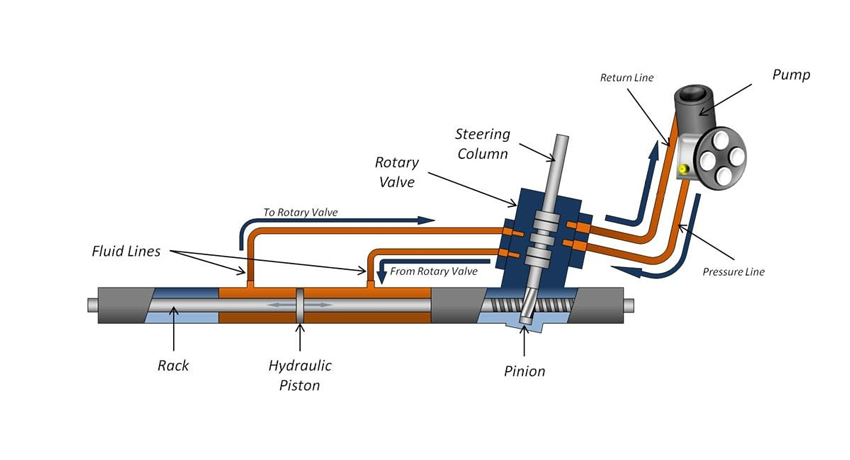

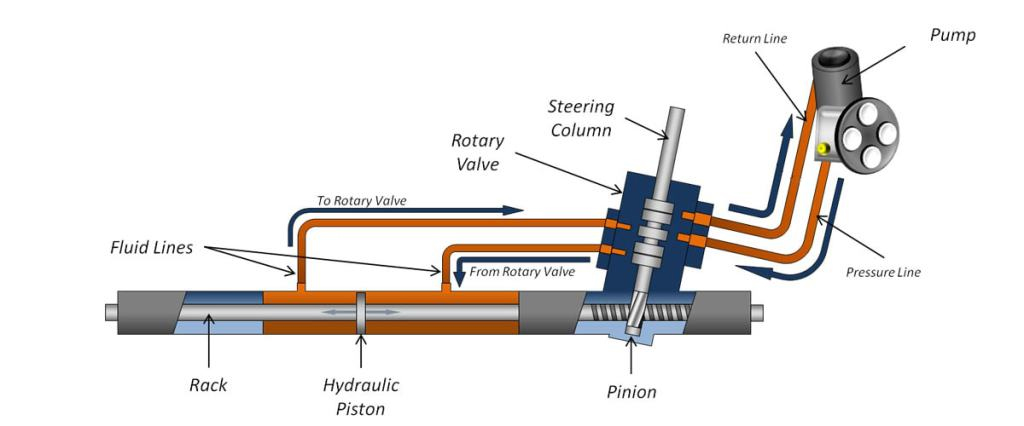

In this type of power steering system, as we discussed before, hydraulic pressure is used to multiply the steering input force to smooth the front wheel steering.

This hydraulic pressure Produced by many components, including hydraulic cylinders, rotor hydraulic pumps, hydraulic lines, high-compression hydraulic fluids, and coupling mechanisms that connect the hydraulic system to the rack and pinion steering system. When the driver turns the steering wheel to provide information, the engine-driven hydraulic pump begins to pump highly compressed hydraulic oil through the pipeline.

The hydraulic pressure generated by the pump enters the hydraulic cylinder, which in turn applies pressure to the piston of the hydraulic cylinder. The piston under high pressure begins to move from one end to the other, pushing additional fluid through the pipeline. With this movement of the piston, the input force applied by the motor increases exponentially. This high-pressure fluid delivered by the hydraulic cylinder exerts pressure on the connected pinion through the coupling mechanism, and then exerts a great force on the rack, and the steering effect occurs on the front wheels.

2. Hybrid or semi-hydraulic power steering system

In this type of power steering system, the hydraulic power steering system is replaced by an electric motor driven pump, which makes it more reliable. This is the only improvement. The principle of operation of this system is the same as that of the hydraulic power steering system mentioned above.

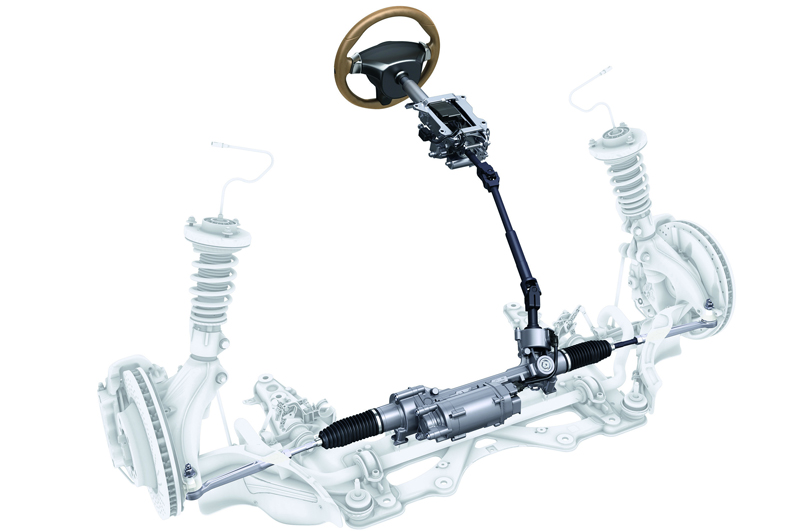

3. Electric power steering system

This system is the last of all steering systems of this type, because we have already commented that the force multiplier is the functional motor of Electric Power Steering instead of hydraulic oil, the system works as follows: Electric Power Steering System Image Source When the driver provides information via the steering wheel, the electronic sensor mounted on the steering column reads the input and sends it to the vehicle’s electrical control unit. The vehicle ECU analyses these inputs and sends a voltage signal to the electric motor located at the end of the steering column, the gear of the electric motor always meshing with the pinion.

Due to the voltage signals sent by the ECU, the engine powered by the vehicle battery starts and provides a specific torque according to the received voltage signal value. After the engine starts, the gear pinion that always meshes with the engine starts to transmit the multiplied torque to the pinion, and then the pinion applies torque to the rack, and the rack is connected through it. The uses the torque applied by the pinion on the rack to move the rack to steer the front wheels as needed.