Disc brakes have a pair of brake pads attached to a calliper, which squeezes down to create friction and slow the rotation of the wheel

Drum brakes are an OG technology that has been around for almost as long as a car. This brake was first developed in 1899 and can be found in some early prototypes made by William Maybach and Louis Renault. For a long time, drum brakes have been the standard means of decelerating vehicles because of their good performance and low production costs.

But in the mid-1960s, when short-range disc brake systems became commonplace, they began to lose the favor of automakers. Nowadays, drum brakes are most commonly found on medium and heavy trucks and buses, and it is expected to recover due to the increasing popularity of electric vehicles. The drum and disc operation is very different and each system has its advantages.

Disc brakes have a pair of brake pads attached to a calliper, which squeezes down to create friction and slow the rotation of the wheel. The disc system is more powerful than the drum and stops faster. This is very necessary, because compared to the rear brake; the front brake will carry 60-80% of the momentum of the decelerating vehicle. This is why you will never find a Front Brake. The discs are also self-adjusting, resulting in less grip or pull, and self-cleaning, making them quieter.

They are also less prone to warping due to prolonged exposure to high temperatures and do not fade in the event of hard braking. In contrast, the drum brake shoes are located in a cylindrical tank, which rotates with the rest of the wheel, and uses pistons to press the two brake shoes outward, wedging them into the inner wall of the drum to create friction. . Reduce the speed of the wheels. Due to the larger surface area inside the cylinder, the drum shoes can be made much larger than disc brake a pad, which makes them have a longer life and exerts greater force than brake pads in calipers.

More importantly, because the drums are located further away on the wheel set, they can easily be used as parking or emergency brakes, while vehicles with four-wheel discs need to add a separate electronic brake. In the latest generation of electric vehicles, drum brakes make a lot of sense.

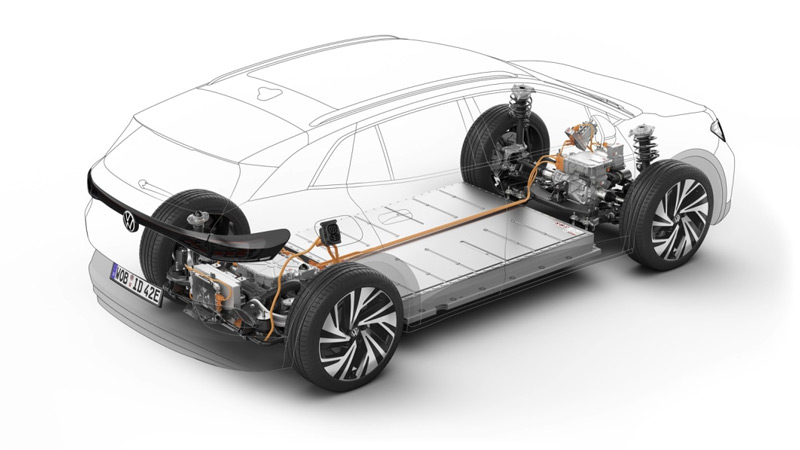

“Drum brakes are designed without residual braking resistance,” a spokesperson for Volkswagen’s North American electric vehicle test team told Engadget. “The shoes are always separated by internal springs. This helps autonomy.” The EV’s regenerative braking system, when you release the throttle, reverses the rear engine (turns it into a generator to charge the vehicle’s battery), which is also functionally compatible with drum brakes.

Volkswagen said that because the electric motor is mounted on the rear axle and automatically decelerates during regenerative braking, the rear brake is generally not used much. Therefore, using brake discs at the rear runs the risk of rust or corrosion when you need them most. Rollers are usually not affected by this problem because they are effectively isolated from the surrounding road environment. A spokesperson for Volkswagen’s brake development department agreed, “Drum brakes look outdated, but for electric vehicles like ID.4, it is the perfect solution.” They pointed out that the brakes the drum has no residual torque and strength, less wear and corrosion, resulting in less brake dust emission than brake discs, which is the main advantage of the brake system.

Dr. Bernhard Klumpp, the head of Continental’s hydraulic brake system business unit, said at a press conference in 2020: “The built-in drum brake in ID.3 has many advantages, especially in the field of electric vehicles. For example, up to 150,000 kilometres. Longer service intervals.”

This is actually the life of the vehicle. In electric vehicles, the weight of the battery pack is the same as that of a U-shaped trailer. Every gram is precious, and every ounce costs. Although disc systems are more effective than drums, they are also much more complicated mechanically, and those additional components, such as independent electronic brakes, increase the quality of the preparation.

Although drum brakes have been evolving since the 1800s, the technology itself has been constantly evolving. Variations of the brake system used by Continental in I. For example, D.4 has been used in six other applications by various OEMs. “Initially, we started to develop [the brake system], including the electronic parking brake…”

Alejandro Abreu González, engineering director of Continental’s hydraulic brake system department, told Engadget. “We have gone one step further. The drum brakes will be fully electromechanical and we will continue to invest in this technology.” Continental previously committed to developing an integrated disc brake system for the electric vehicle market in 2017.

The company explained in a press release at the time: “The rim consists of two aluminium parts. The inner aluminium star wheel has aluminium brake discs, and the outer aluminium rim complements the tires.” Compared to the brake, the new brake wheel concept actuates the aluminium disc from the inside. This gives it a particularly large diameter, which improves braking performance.”

Although the new wheel was never put into production, this work “really made us feel better. There is a lot of knowledge about new materials that reduce weight,” said González. “That’s for sure, with heavy batteries, we will have to keep developing.” González admitted that it is still a challenge to change the public perception that drum brake technology is outdated and inferior to disc brakes. However, although we may never see the return of the four-wheel drum system, especially in any sporty and high-performance vehicles, “For urban driving, I think this is the best technology that makes sense for electric vehicles.